|

A Summary of VDE 0816

Outdoor cables for telecommunication and information systems , Signalling and Measuring cables and Mine cables .

Scope

This Standard applies to outdoor cables for telecommunications and information processing systems, divided into the types “signalling and measuring cable” and “mine cable”.

It does not apply to cables in respect of the make-up and properties of which special requirements are laid down for electrical or mechanical reasons.

Signalling and measuring cables :

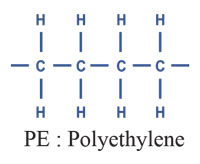

The cables are stranded in layers and contain as stranding components cores with copper conductors 0.9 or 1.4 or 1.8 mm in diameter. The conductor insulation is of PE .

1) Conductor

The conductor is plain solid annealed copper ; usually 0.9 , 1.4 mm (0.8 , 1.8 mm also available).

The conductors must be of soft copper and of completely satisfactory quality, The breaking elongation of the conductors in the cable must be at least 15%. Any joints present must not impair the completely satisfactory nature of the conductor. The tensile strength of a joint within a conductor must be at least 90% of the tensile strength of that conductor without a joint.

|

2) Insulation

The PE insulation must comply with compound 2YI1 in accordance with DIN VDE 0207 |

|

|

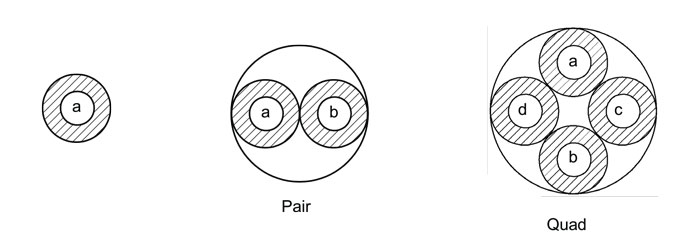

3)Cabling element

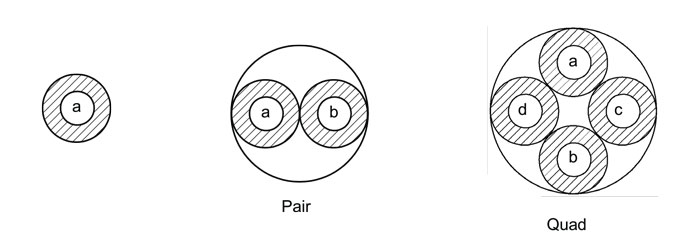

A cabling element shall be an insulated conductor (core) to build up a multi-core cable

– a pair of two insulated conductors twisted together and designated wire a and wire b

– a quad (star quad) of four insulated conductors twisted together and designated wire a, wire b, wire c and wire d respectively.

The stranding components are counted successively in the same direction through all the layers, starting with the first layer (inner layer). In doing this, start from the initial component in each layer

|

|

4)Stranding

The cable elements shall be formed into a number of sub-units or units which can be stranded into a regular make up to produce the required number of cores , pairs or Quads .

5)Filling

For filled cables (if Requested) , the interstices of the cable core shall be filled continuously with a compound suitable to prevent water penetration within the cable.

6)Core protection

The core of the cable may have a protective layer (e.g. a helical or longitudinal lapping of one or more tapes).

7)Shield (protection against electromagnetic fields)

The Shield of cable is selected to comply requirements of requested reduction factor . It could be ; Copper Tapes or Copper Wires .

|

|

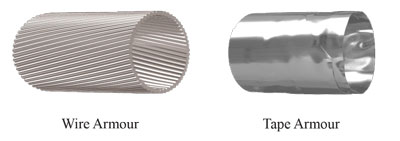

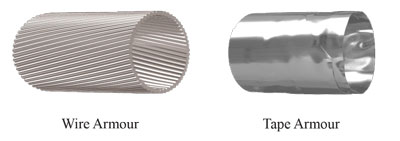

8)Armour (protection against mechanical damages)

When required by the relevant sectional specification the armouring shall consist of one or more of the following:

8-1) layer of round galvanised steel wires;

8-2) single or a double layer of steel tape

|

|

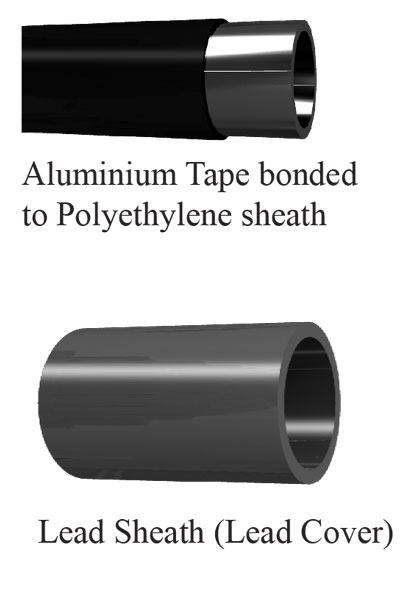

9)Sheath

The inner-sheath and outer-sheath of cable is usually PVC.

The PVC sheath must comply with compound type YM1 in accordance with DIN VDE 0207 Part 5.

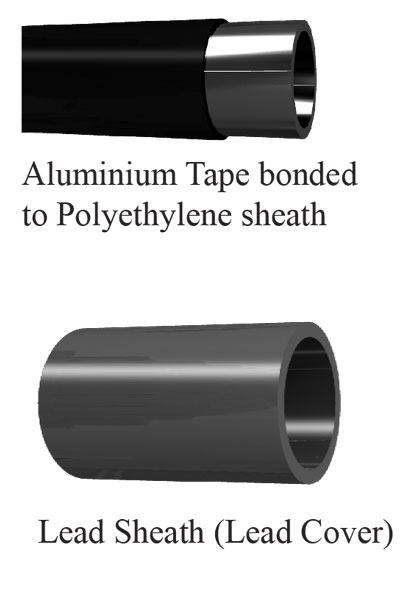

-Optional : A moisture barrier aluminium laminated polyethylene sheath construction is specified for both underground and aerial cables. This type of sheath will also provide screening.

-Optional : A lead sheath could be provided for extra shield and protection against penetration of liquids and chemicals to cable core.

|

|