|

A Summary of IEC 60092-376 (2003)

Electrical installations in ships - Part 376: Cables for control and instrumentation circuits 150/250 V (300 V)

Scope and object :

This part of IEC 60092 is applicable to screened and unscreened cables for control and instrumentation circuits on ships and offshore units.

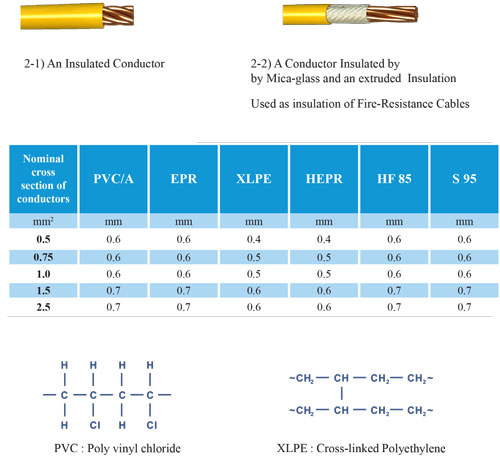

The cables have extruded solid insulation with a voltage rating of 150/250V (300V) and are intended for fixed installations.

Rated voltage :

The standard rated voltage Uo/U (Um) is as follows:

Uo/U (Um) = 150 V/250 V (300 V) a.c.

In the voltage designation of cables ;

Uo : is the rated power-frequency voltage between the conductor and the earth or metallic covering for which the cable is designed;

U : is the rated power-frequency voltage between conductors for which the cable is designed.

Um : is the maximum value of the highest system voltage for which the equipment may be used.

A d.c. voltage up to a maximum of 1.5 times the a.c. voltage may be used, provided that the voltage to earth does not exceed 250 V.

1 ) Conductors :

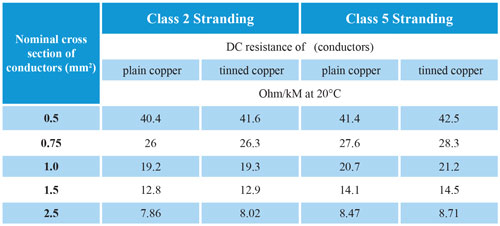

The material, metal coating, separator, class and form of the conductors shall be in accordance with IEC 60092-350 and shall be circular Class 2 or Class 5 constructions of cross-sectional area 0.50 mm2, 0.75 mm2, 1.0 mm2, 1.5 mm2 or 2.5 mm2.

Note : The preferred conductor sizes are 0.75 mm2 and 1.5 mm2.

|

|

3 ) Cabling

3-1 ) Core assembly (multicore cables)

The individual cores shall be twisted together in concentric layers.

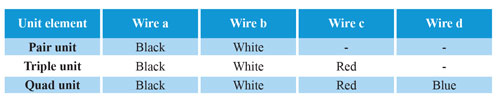

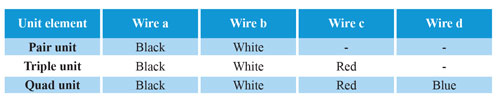

3-2 ) Forming pair, triple or quad units ;

Cores shall be twisted together with either a left hand or right hand lay to form a pair, triple or quad unit.

The lay length of the cores individually or collectively screened shall not exceed 120 mm for sizes below 1.5 mm2 and 150 mm for sizes 1.5 mm2 and above.

|

|

3-4 ) Number of cores

It is recommended that the number of cores shall be selected from one of the following: 2, 4, 7, 12, 19, 27, 37.

3-5 ) Number of pair, triple or quad units

It is recommended that the number of pair units shall be selected from one of the following: 1, 3, 7, 12, 19, 27, 37.

4 ) Electrostatic screen

4-1 ) Individually taped screened pair, triple or quad constructions

When an individual taped screened pair, triple or quad construction is required, each pair, triple or quad shall have a laminated electrostatic screening tape applied with the metallic side in electrical contact with a drain wire. The nominal overlap shall not be less than 25 %.

The laminated electrostatic screening tape shall be either aluminium bonded to polyester having a minimum thickness of aluminium of 0.008 mm and a minimum thickness of polyester of 0.010 mm, or copper bonded to polyester having a minimum thickness of copper of 0.018 mm and a minimum thickness of polyester of 0.023 mm.

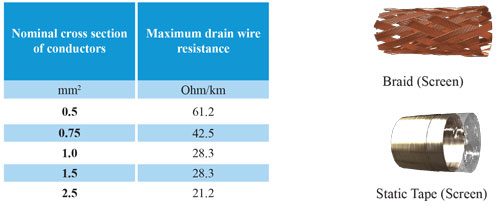

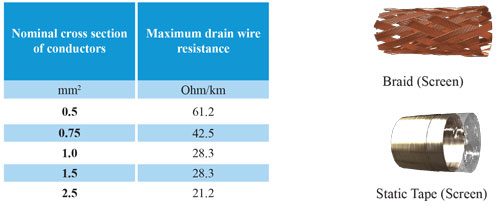

The drain wire shall be composed of a number of strands of tinned annealed copper wires in the case of aluminium laminate tape and either plain or tinned annealed copper wires in the case of copper laminate tape.The drain wire shall have a maximum resistance in accordance with following Table .

|

|

4-2 ) Individually braided screened pair, triple or quad constructions

When an individual braided screened pair, triple or quad construction is required, each pair, triple or quad shall have a non-hygroscopic separator tape applied over the cores and under the braid.

The nominal overlap shall not be less than 25 %.

The braid shall be either plain or metal coated copper wires; the minimum diameter of the braid wire shall be: When required, to aid termination, a drain wire may be applied under and in direct contact with the braid screen.The drain wire shall be composed of a number of strands of tinned or plain annealed copper wires. The drain wire shall have a maximum resistance in accordance with following Table .

|

|

4-3 ) Collectively screened constructions

Similar to 4-1) and 4-2) ; both taped and braided screen’s type is permitted .

5 ) Metal braid armour

In this standard the braid wires are either:

zinc coated (galvanised) steel , or

copper (plain or tinned),

Note : In the case of plain or tinned copper wire braids, these may also provide the function of an electrostatic

collective screen providing they are terminated to earth.

|